Moreover, you will know how to improve existing network with current technology to be more efficient. In this course, you will learn principal of CC-Link IE Control network system which enable the communication among Mitsubishi PLC, Configuration of PLC Parameter and PLC programming to send-receive data between PLCs in the network. Furthermore CC-Link IE Control is one of network system standard which convenient to use, highly reliable and easy for troubleshooting. Therefore, it is essential to connect PLCs of each process into network system in order to transfer data with the speed up to 1 GB to enhance production efficiency. Nowadays, the factory automation system is needed for every factory in which need the conformity of each production line. This course sets up for people who would like to know how to utilize PLC into network as connectivity in Control Level Network or as known as CC-Link IE Control. Page top CC Link IE Control (CCIEC301-MELFT16) PLC simulation kit (Q-Series) and QD81DL96 6 sets Basic knowledge in Microsoft Excel software.Complete PLC201 course (Advance PLC) or have advanced PLC's knowledge and have experiences in GX Works2 software.

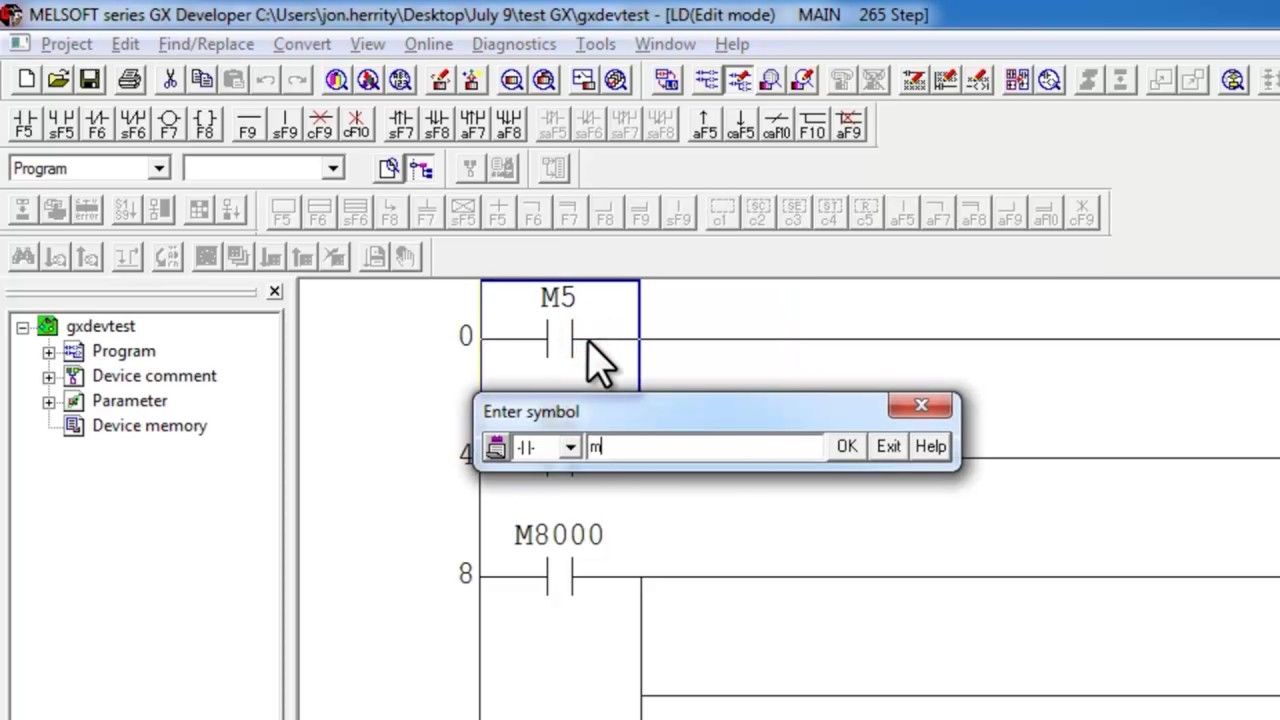

GX WORKS 2 PARAMETER SOFTWARE

Those data in the software will help to analysis the operation for the maintenances. This course will introduce the PLC data collection then displaying in graph format, concentrate on the systems those have Mitsubishi-International-Standard PLC network. This course, the trainees will able to receive data through the Ethernet communication. This course suites for users who are interesting in using High speed data logger for logging FX-Series or Q-Series PLC data by using logging Function, GX Logviewer and High Speed Data Logger Module Configuration Tool as a medium. Training Time: 09.00-16.30 (Please present before the session begin for 30 minutes to register)

Therefore this will be one of the best opportunities for trainee to have direct experience in this course. In this course, the trainees will study from and use the real equipment from our kit set. Moreover, the trainees will be able to check and troubleshoot the problems once there are any problems occur. Trainees of this course will apply knowledge of PLC which will be advantage in model selection and using a special module of PLC Q series. This course has been set up for the advancer who is interested and would like to know the advance knowledge of PLC. Remark:Course detail may be changed without prior notice PLC kit set (FX-Series, and Q-Series PLC) 16 sets

Basic knowledge in electrical system or experience in measuring or controlling system.Basic PLC equipment (Input, Output, Internal Relay, Timer and Counter).Design PLC system control and PLC's programming.How to select the most appropriate PLC model.PLC fundamental, structure and type of PLC.Therefore this will be one of the best opportunities for trainee to have direct experience with PLC. In this course, the trainees will study from and use the real equipment. Moreover, the trainees will be able to check and troubleshoot the basic problems once there are any problems occur. Trainees of this course will acquire basic knowledge of PLC which will be advantage in model selection and using PLC. This course has been set up for the beginner who is interesting and would like to know the basic knowledge of PLC. Training Calendar BASIC PLC (PLC101-MELFT13) Please refer to Training Calendar for details.

0 kommentar(er)

0 kommentar(er)